Cleaning stainless steel parts for UHV

This is a summary of this document, which is in German. It deals mostly with cleaning 1.4301 stainless steel. I added some bits from personal experience.

You need to know the pumping speed of your pump. Typical value is for a small, 2500€ turbo pump. Knowing the pumping speed and the inlet pressure , you can calculate the pump throughput .

In typical UHV applications, the pumps must deal with the leak flow rate .The actual vacuum in far ends of the system then depends on the conductivities of the pipes. Conductivities are 1/(Resistance) and have the same unit as the pumping speed. Important distinction: Throughput depends on pressure difference:

The leak rate can be caused by

- mechanical leak: Typical value is for a hair placed on the O ring of a KF flange. The leak rate can easily be 5 orders of magnitude larger, and you still won't here a hissing sound. You can find leaks using snoop leak checking fluid. Smaller leaks need a helium leak checker to find. Typically, you can avoid or close leaks.

- permeation of gas (helium) through bulk material: Stainless steel parts thicker than a few mm won't have this problem. O rings show leak rates of when you spray them with helium for more than 20 seconds or so.

- diffusion of gases trapped in bulk material to the outside: Hydrogen atoms leak towards the vacuum with typically a few . Note that I used the area normalized leak rate here. This can be reduced by baking the parts in vacuum.

- desorption of material trapped/smudged on the surface. Usual suspects are water, carbohydrates, and heavy metals. A cleaned and baked stainless steel part still outgases water with , although the exact value depends a lot on the cleaning method.

You are also worried about particles trapped on the surface, from lints of cleaning wipes, dust particles, particles in cleaning water, glove abrasions, ... These particles can be a source of outgasing, they can disturb semi-conductor manufacturing processes, and (relevant for physicists) trap surfaces charges that disturb beam-optics of low energy (<100eV) beams. I am going to neglect particles here: If you want to get serious about them, you need a clean room. Other than that, lint free wipes and deionized (purified) water help a lot.

Countermeasures: Better than cleaning is to avoid contamination. Use only tools, holders, and machining oils that are free of heavy metals when manufacturing the parts. Use deionized (purified) water only. Cleaning helps to combat desorption of surface material and removes particles. Baking helps with surface desorption as well, and with diffusion of gases trapped in the bulk metal.

Coarse cleaning: Pressure washer, wire brush, turning in a lathe, milling until the surface looks nice. Wipe everything down with lint-free wipes.

Fine cleaning: Always clean in ultrasonic bath as the last step. Before that, you can do:

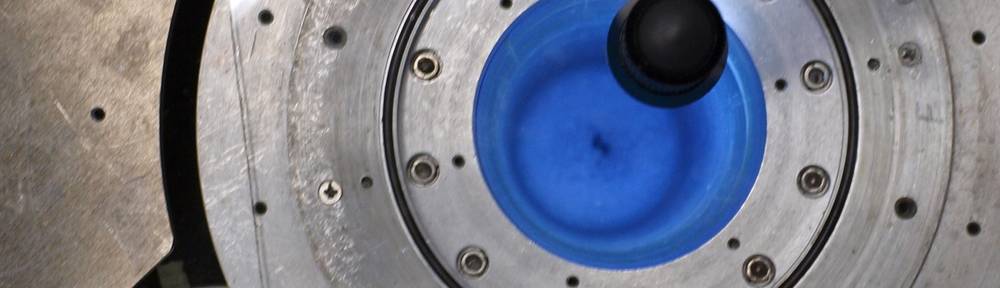

- Electro polishing: Using a bath with the right electrolyte and a suitable electrode structure smooths the surface (larger field gradient near edges). Creates a thin chrome-oxide layer that acts as a diffusion barrier for hydrogen. Not too effective in removing hydrocarbons.

- Mechanical polishing: Smooths the surface and takes off hydrocarbons with it. Only drawback: Does not create a barrier agains hydrogen diffusion from the bulk.

- Bead blasting removes the top surface layer and any hydrocarbons with it. But surface will be rougher compared to electropolishing or mechanical polishing, so expect more outgassing of water. Creates dust particles that are tricky to remove.

After everything is mounted, bake out. Higher is better, 300°C is a bit impractical, but works rather quickly (only a few hours needed).

So much for the suggested procedure. Here is what we do:

- Workshop does no polishing of the parts, but machines the surfaces carefully in the last go of the lathe/milling machine. Degreases them using several rounds of ultrasonic bathing and drying in an oven.

- We get the parts, and if they are small enough, ultrasound them in a bath of isopropanole, water, and acetone (in no specified order). If they are big, we just wipe them down with isopropanole, then acetone.

- We use nitrile gloves to handle the parts and aluminum foil to put them down or to wrap them.

- We mount the parts. For technical reasons, we don't go above 120°C when baking. Often we bake at only 50°C for two weeks.

Using a small 80l/s pump on a 1.5m long, stainless steel beamtube with 2cm diameter, and two 8cm diamater, 30cm long chamber on each end, we easily reach and below. Caveat: We measure near the pump - so on the far end of the tube, vacuum is worse. Once we dip the far end into liquid helium, our vacuum is too good to measure. We don't see any ion loss with Carbon4+ or Oxygen5+ ions, and can store single ions over weeks.